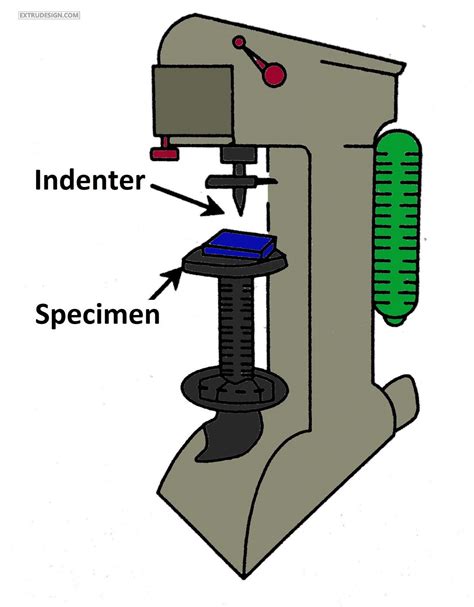

limitations of brinell hardness test and why|brinell hardness number chart : import In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. The Brinell Hardness Test method is the most commonly used hardness measurement .

The Class B model comes with a Virus Protection Shield cycle, which heats the trays up to 180° for 15 minutes. This method eliminates bacteria, viruses, and fungi - including coronavirus - for more thorough sterilization.

{plog:ftitle_list}

Sterile tools and a sterile environment are one of the most important parts of tattooing. We carry tattoo sterilization equipment like sterilization pouches, tattoo autoclave cleaner and tape, spore test kits and more from brands like .

The Brinell Hardness Test method is used to evaluate the hardness of the .What is Brinell Hardness Test? The Brinell Hardness Test is a way to measure how hard a material is by pressing a hard ball into it and seeing how big the dent is. What are the advantages and disadvantages of Brinell Hardness Test

Understanding the limitations of the Brinell Hardness Test is essential for mitigating potential errors and ensuring the reliability of hardness measurements. l Longer testing time: Generally speaking, the Brinell test requires more time . Brinell hardness testing has its limitations, however, including the need to use a selection of different-sized indenters depending upon the material under test and, sometimes, it’s not suitable for testing very small components.In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. The Brinell Hardness Test method is the most commonly used hardness measurement .

brinell hardness testing procedure

The Brinell test has several limitations; 1. Cannot be used on soft materials. 2. The test may .Brinell testing of a material with different ball diameters and test forces must be conducted within the same force-diameter index ("Brinell test procedure") in order to enable direct comparison of the measured hardness values. EN ISO 6506-1 is a European standard that specifies the requirements for .

yellow tips/ yellow pipette tips

In this article, we have seen the Brinell hardness test and its two different methods – Standard and Non-Standard Brinell hardness tests. Also, discussed its advantages, disadvantages or limitations, and applications.The Brinell Hardness Test method is used to evaluate the hardness of the object, especially for non-ferrous metals, cast irons, and steel products at the higher strength ranges and aluminum and copper alloys at lower strength ranges. But it cannot measure extremely hardened materials like .What is Brinell Hardness Test? The Brinell Hardness Test is a way to measure how hard a material is by pressing a hard ball into it and seeing how big the dent is. What are the advantages and disadvantages of Brinell Hardness TestUnderstanding the limitations of the Brinell Hardness Test is essential for mitigating potential errors and ensuring the reliability of hardness measurements.

brinell hardness testing method

l Longer testing time: Generally speaking, the Brinell test requires more time than Vickers or Rockwell methods for determining hardness. l Requires more maintenance: Regular replacement of the. Brinell hardness testing has its limitations, however, including the need to use a selection of different-sized indenters depending upon the material under test and, sometimes, it’s not suitable for testing very small components.In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. The Brinell Hardness Test method is the most commonly used hardness measurement technique in the industry.

The Brinell test has several limitations; 1. Cannot be used on soft materials. 2. The test may not be valid for thin specimens. The minimum thickness is about 0.313 in. 3. The test is not valid for case hardened materials. 4. The test should not be conducted too close to the edge of material. 5.Brinell testing of a material with different ball diameters and test forces must be conducted within the same force-diameter index ("Brinell test procedure") in order to enable direct comparison of the measured hardness values.

EN ISO 6506-1 is a European standard that specifies the requirements for metallic materials' Brinell hardness testing. It outlines the testing method, equipment, calibration, and procedures for determining the Brinell hardness of metallic materials using test forces between 1.96 N and 29420 N. In this article, we have seen the Brinell hardness test and its two different methods – Standard and Non-Standard Brinell hardness tests. Also, discussed its advantages, disadvantages or limitations, and applications.

The Brinell Hardness Test method is used to evaluate the hardness of the object, especially for non-ferrous metals, cast irons, and steel products at the higher strength ranges and aluminum and copper alloys at lower strength ranges. But it cannot measure extremely hardened materials like .

What is Brinell Hardness Test? The Brinell Hardness Test is a way to measure how hard a material is by pressing a hard ball into it and seeing how big the dent is. What are the advantages and disadvantages of Brinell Hardness Test

Understanding the limitations of the Brinell Hardness Test is essential for mitigating potential errors and ensuring the reliability of hardness measurements.

l Longer testing time: Generally speaking, the Brinell test requires more time than Vickers or Rockwell methods for determining hardness. l Requires more maintenance: Regular replacement of the. Brinell hardness testing has its limitations, however, including the need to use a selection of different-sized indenters depending upon the material under test and, sometimes, it’s not suitable for testing very small components.In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. The Brinell Hardness Test method is the most commonly used hardness measurement technique in the industry.The Brinell test has several limitations; 1. Cannot be used on soft materials. 2. The test may not be valid for thin specimens. The minimum thickness is about 0.313 in. 3. The test is not valid for case hardened materials. 4. The test should not be conducted too close to the edge of material. 5.

yellow universal pipette tips

Brinell testing of a material with different ball diameters and test forces must be conducted within the same force-diameter index ("Brinell test procedure") in order to enable direct comparison of the measured hardness values.

brinell hardness testing machine diagram

yellow vwr pipette

you fill a pipette with what

For syringes that can be autoclaved, they need to be disassembled prior to autoclaving. 1 Recommended disinfecting chemicals are Microcide SQ ® (p/n 3995-01), 10% bleach, .50- and 15-ml falcon tubes can be autoclaved and re-used. Please refer to the chart below for the protocol. I would not recommend using these tubes to prepare and store complete media because of the high risk of contamination.

limitations of brinell hardness test and why|brinell hardness number chart